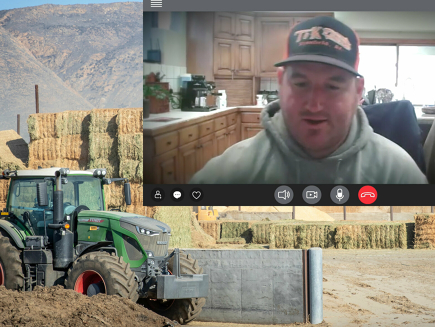

It’s early—pre-sunrise—on a Wednesday morning at Ramona Dairy in San Jacinto, California. A big Fendt tractor is making the rounds with a mixer wagon already. It helps deliver some 40,000 pounds of feed to the 4500 head of cattle onsite at this location of the De Jong family’s dairy operation. This is one of 11 locations for this branch of the De Jong family tree; the Dutch surname is known country-wide and has become synonymous with milk production.

“Most of the De Jongs in the United States are my relatives,” says Josh De Jong, who owns and manages the two locations of Ramona Dairy. His father, Arie, runs the well-known Hollandia Dairy in San Marcos. “This has been in our blood for a long time,” says Josh. “My family still milks cows in the same barn in Holland since 1620, so we’ve been milking cows for more than 400 years.”

The first De Jongs came to the United States in 1949. Legend has it the patriarch arrived stateside with $32 in his pocket. “My grandfather came with nine of his siblings and they started fresh,” Josh says. Hollandia is one of the oldest independent milk processors in California and is also the last processing plant in San Diego County. Ramona is fairly new in the chain; Josh has operated it for about 10 years. Along with the 11 dairy sites across California and Arizona, the De Jongs also farm some 35,000 acres across the two states.

The family survives—and thrives. Josh is one of Arie’s four children. “I’ve got three sisters. They’re all in the dairy business,” says Josh. “One of my sisters’ husband runs a few of our dairies for us, he’s the main man for my dad in Arizona. Me, my three sisters, my parents… we make it all happen.”

Most early mornings like this one, Josh is driving around among the tractors and feed wagons in his “three quarter-ton office,” he says (his truck—Josh says running a dairy is not a “desk job, ever”). It’s his favorite part of the job, “checking on things and making sure things are running smooth,” he says. His least favorite part? “Paying the bills,” he laughs, then turns serious. “It’s a battle to keep it all afloat.”

California is the nation’s top agricultural state, and dairy is the state’s top farming practice. It’s worth $20 billion to California’s economy. But ever-tighter environmental regulations, labor challenges, fights over water use coupled with historic drought… it’s all part of the “battle” Josh describes. While California still leads the nation in milk production, growth in the state’s industry is stagnant. The challenges to some in the state are existential, as dairy operators sell or convert to row crops; the survivors are left grappling for new efficiencies.

“There are a lot of things that contribute to the efficiency of your farm,” says Josh. “It takes good employees, good training, a lot of people,” he says. Josh does rely on “good people” like Andrea Van Hattem, who runs the front office for Josh at Ramona. She and Ramona’s operations manager, Hector Gutierrez, have their finger on the pulse of the day-to-day at the dairy. When the conversation turns to the specifics of feeding and production, Van Hattem calls Gutierrez and they converse about daily inputs and outputs on speakerphone:

4,500 head.

106 pounds of feed per head, per day,

90 pounds of milk output per head, per day.

Six loads of milk shipped per day.

A half million pounds of feed, every day, just at this location. That’s why that big feed mixer starts pre-sunrise, usually around 3 in the morning.

Alfalfa grows on the “lawn” in front of Ramona, which will soon harvest and go to green chop. Thousands of acres of alfalfa are grown elsewhere on family and leased land, as well as corn for silage. Mixed with that, says Josh, are byproducts found locally: Almond hulls, citrus, distiller’s grain.

Van Hattem grew up in the dairy industry in California, but her family is among those who have decided to leave the state and put down dairy roots elsewhere. While she says doing business in California is getting “harder and harder,” she does understand and appreciate that “California is working really hard on air quality.” It’s one of the efficiencies the business has tapped into: “California has a program that helps farmers change their equipment out to something that is better for the environment, less emissions,” she says.

Every bit helps, says Josh. “We got feed prices on the rise, fuel prices on the rise. (We’re) constantly having to change what we do every day… Figure out ways to be more efficient. It’s very volatile. We love what we do, otherwise we wouldn’t do it. But it’s a constant battle.”

Story by Jamie Cole

Scroll down to learn how Ramona Dairy transitioned to Fendt tractors to help make the operation more efficient >>