Brad Rill remembers having great admiration for Lippy Brothers Farms even before he married into the family and became a part of the business. “I grew up here,” Rill says of the fertile ring of farmland around Baltimore, in the Chesapeake Bay watershed. “I was always fascinated with Lippy Brothers Farms. They were one of the biggest, premiere farms in our area. They had different ideas.”

Being one of the biggest, premiere farms in the area means something different than it did back when Lippy Brothers incorporated in 1965, but the status hasn’t changed. Today, the business is farming some 8,000 acres of land, producing almost 30,000 dozen eggs a day, and exporting near 3 million bushels of soybeans a year for farmers in the area. The numbers alone prove the farm has “different ideas” … “always very innovative,” says Rill. “Willing to try new things.”

Perhaps that came naturally from the start, because the family never shied away from the input of diverse voices. Four Lippy brothers—Donald, Ed, Joe and Wilson—began farming together right out of college and “they were all a little different,” says Rill. Their sister, Betty, even ran the front office for 40 years.

“In the early times, we did a lot of fresh market stuff, tomatoes, sweet corn,” Donald Lippy recalls. He and his brother Ed are the remaining brothers and are still owners in the business. “We did peas for a while, then snap beans,” he says. Today, the snap beans remain a big part of the business, some 1,200 acres. But the rest of the operation has grown, and diversified.

While acreage can vary from year to year, especially given the development pressures of being only 20 miles northwest of Baltimore, the commitment to diversity of crops remains: Corn, wheat, barley, green beans for a local cannery, some straw and hay, and soybeans, some double-cropped and some full-season.

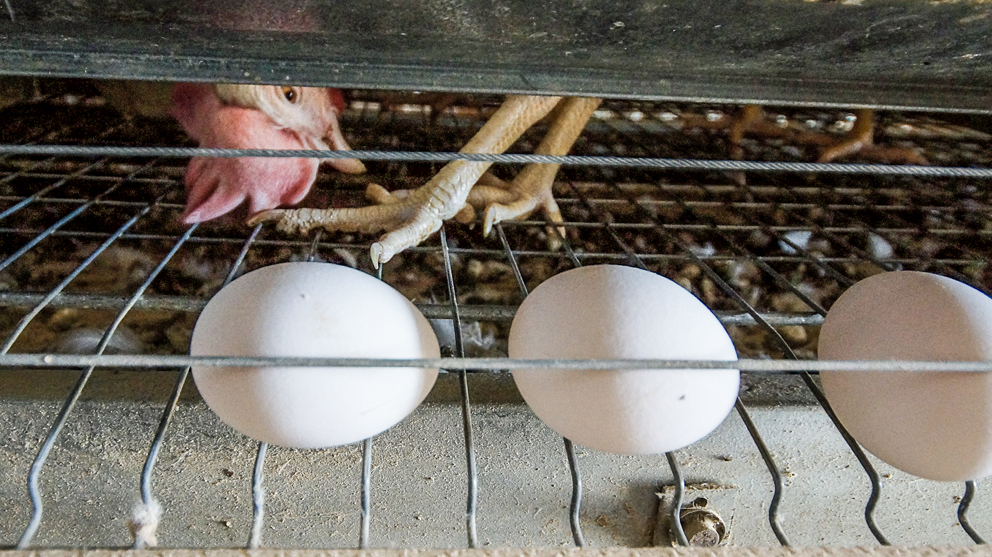

Rill remembers that the business was already impressive when he married Donald’s daughter, Tracey, in 1992. He had been working for the farm; “I started by picking up rocks,” he laughs. Around that same time, another opportunity presented itself, and the growing family answered the call. “We were approached about getting into the chicken business, laying hens,” Rill says. Never bashful about taking the full dive, the Lippys went all in with “500,000 birds in the beginning,” says Rill, about 125,000 birds in four large houses. Today, regulation keeps the population to 100,000 birds per house, but “the thing that’s mind-boggling to me is that, on average, those four chicken houses produce about 29,000 dozen eggs a day,” he says.

The addition of the chicken business paid off in fertility practices, as well. “We get about 5,000 to 7,000 tons of really good, high-quality litter every year,” Rill says. Applying 2 to 3 tons to the acre means about every third year they are making the full rotation of all their farmland with the manure. The practice saves on commercial fertilizer and maintains nutrient value on both owned and rented land, which Donald says the family treats equitably.

Conservation Benefits Everyone

“We rent a bunch of ground,” says Donald, and he and Brad both admit that finding land to farm is a challenge. “When you’re doing stewardship right, taking care of the land, keeping fertility up… It’s easier to rent somebody’s farm if they see what you’re doing and think you’re doing a good job,” he says.

They’ve installed grass waterways and enter the Maryland Cover Crop program every year. Their favorite is a mix of oats and tillage radish that keeps no-tilled soil loose, and Rill says “we’ve even thrown in some sunflower because it looks so good.” That combination also dies off naturally there in winter, saving on herbicide use. Meanwhile, more than 2,000 acres are in ag preservation easements to fend off development, and the USDA Conservation Reserve Enhancement Program takes some of their less profitable land out of production and preserves it as natural buffers to protect streams from chemical runoff.

“Those are pretty common practices in our area,” says Rill, reflecting the stewardship to which farmers in the Chesapeake basin are committed. But Rill says the Lippys were among the first to implement no-till, and are still held up as examples of practices that are commonplace in the area now.

Farmers Working For Farmers

Rill says you’ll most often find him and Donald around the shop and office or in the field, depending on the time of year. Tyler Rill, Brad’s son, finds himself a little more tied to a single location, thanks to perhaps the best example of the Lippys’ diversification and innovation. A grain storage complex across the road from the Lippy Brothers’ main office has become a popular destination for the area’s soybean farmers.

“I was still young,” says Tyler, 14 years ago when the Lippys first dipped a toe into the soybean export business. Today, Tyler is helping handle all of the grain that comes in and out of the Lippys’ farm, as well as some 3 million bushels of soybeans from surrounding farms. Tyler says the volume isn’t quite comparable to what you’d expect at, for example, a Midwest grain elevator, but “for this area, we move,” he laughs, noting that the lines to fill shipping containers with beans at the Lippy facility can loop across the road and around the office during harvest. “If we did it 24/7 in September, October… people would do it,” he laughs.

Donald says the Lippys got into exporting soybeans through a connection with the University of Maryland’s department of agriculture. Recognizing the family’s willingness to try new things, “they sent a guy up here who was in the export business, and talked to us about doing it,” says Donald. They started slow, filling containers with beans that run by truck to Baltimore’s port, and from there to wherever brokers find the market for them. Tyler says he sees paperwork that shows destinations like Taiwan, Indonesia, Malaysia, Nepal… mostly for soy protein. Like at any grain facility, growers can sell to the Lippys on contract or spot price. The family handles the rest.

There’s an advantage for both parties when farmers are working with and selling to farmers, says Tyler. “At the end of the day, we all have the same goal. And so we have a good relationship with the farmers in this area… Everybody’s trying to help each other out any way they can.”

“We’ve always been fairly diversified,” says Donald, but then seems to recognize the understatement immediately: “We try to follow the trend, maybe be ahead of the trends, a little bit, and it’s worked out pretty good,” he says, with a smile.

Like his father, Brad, Tyler is well aware of the Lippy legacy of innovation, and what it means to be a part of it. “I know I can speak for my brothers on this, too,” he says. “We want to make sure we can continue to fill the shoes of my grandfather, his brothers, and my dad… because without them, we wouldn’t be where we are today. So it’s pretty cool. It’s a pretty cool thing.”

Story by Jamie Cole