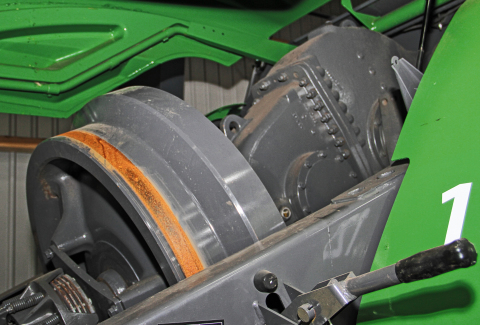

The Fendt 1290 XD has a flywheel, which is almost twice as heavy as that on the standard model. The heavy flywheel puts extra straw in the bales, as Jørgens Maskinstation A/S at Grindsted has found out.

The Fendt 1290 XD is built like a genuine big-bale presser at the Hesston plant in North America. But instead of the usual 120 x 130 cm bales, the Fendt 1290 XD delivers bales with a width of 120 cm and a height of 90 cm. ‘XD’ stands for ‘Xtra Density’, and that means up to 20% extra straw in the bales.