Resource-saving, cost-effective, high-quality and higher yield operations – the demands on farming are continually climbing. To meet them, agricultural enterprises have been relying more and more on precision farming.

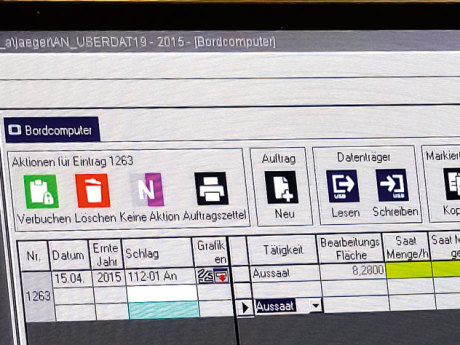

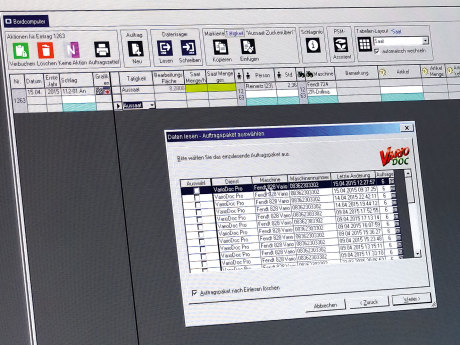

The AGCO Corporation has developed the Fuse® Technologies strategy for this. It provides agricultural enterprises with seamless integration and connection of their entire fleet. This includes the Variotronic operating interface, which includes the applications VarioGuide, VarioDoc Pro, SectionControl, VariotronicTI automatic and ISOBUS. Modern agricultural enterprises like the Westfarm GbR in Geilenkirchen, Rhineland, demonstrate how they are successfully implementing these technologies.