Me and my Fendt.

Behind every Fendt machine there is a special story. Wherever it is about work or the circumstances its operator has to battle against – one thing sets them apart: together, as a team, they have succeeded. We have collected true stories from Fendt customers and Fendt operators here for you – a true experience.

You can find customer testimonials from older series HERE.

The tractor knows how much horsepower it needs at any given second and the fuel efficiency is second to none.

Wes & Wesley Vanfossen, farmers, Kimbolton, Ohio, USA - Fendt 516 Vario Tractor

Wes & Wesley Vanfossen, farmers, Kimbolton, Ohio, USA - Fendt 516 Vario Tractor

The tractor knows how much horsepower it needs at any given second and the fuel efficiency is second to none.

What has set Fendt equipment apart for us in our operation is the service that we get.

Kerry, Hade & Loretta Lyons, farmers, Tompkinsville, Kentucky, USA - Fendt IDEAL Combine, Rogator Sprayer, and 933 Vario Tractor

Kerry, Hade & Loretta Lyons, farmers, Tompkinsville, Kentucky, USA - Fendt IDEAL Combine, Rogator Sprayer, and 933 Vario Tractor

What has set Fendt equipment apart for us in our operation is the service that we get.

We are probably saving 30% to 40% in fuel over what we were running with some of our other tractors

Setniker Family, farmers, western Oregon, USA - Fendt 314, 516, 718, 724, 933, 942, 1050 and 1167 Vario Tractors

Setniker Family, farmers, western Oregon, USA - Fendt 314, 516, 718, 724, 933, 942, 1050 and 1167 Vario Tractors

We are probably saving 30% to 40% in fuel over what we were running with some of our other tractors

We're not afraid of change. We are trying to do what's right for our farm.

Steve & Chad Nuest, farmers, Hancock, Minnesota, USA - Fendt IDEAL Combine, 1046, 1050, and 930 Vario Tractors

Steve & Chad Nuest, farmers, Hancock, Minnesota, USA - Fendt IDEAL Combine, 1046, 1050, and 930 Vario Tractors

We're not afraid of change. We are trying to do what's right for our farm.

Going from two combines to one Fendt really made it a lot easier for our manpower at harvest time.

John Hamill & Family, farmers in Penhold, Alberta, CANADA - Fendt IDEAL Combine

John Hamill & Family, farmers in Penhold, Alberta, CANADA - Fendt IDEAL Combine

Going from two combines to one Fendt really made it a lot easier for our manpower at harvest time.

Fendt has increased our efficiency and decreased our costs, and it doesn’t get any better than that.

Dave Justison, farmer, Illinois - Fendt IDEAL Combine, Momentum Planter, 314, 1038, 1050, 1151, and 1167 Vario tractors

Dave Justison, farmer, Illinois - Fendt IDEAL Combine, Momentum Planter, 314, 1038, 1050, 1151, and 1167 Vario tractors

Fendt has increased our efficiency and decreased our costs, and it doesn’t get any better than that.

You’ve got to keep improving every day; otherwise, you get stagnant.

Jim Panek, farmer, western New York, USA - Fendt Rogator Sprayer, 943, 1162, and 1167 Vario tractors

Jim Panek, farmer, western New York, USA - Fendt Rogator Sprayer, 943, 1162, and 1167 Vario tractors

You’ve got to keep improving every day; otherwise, you get stagnant.

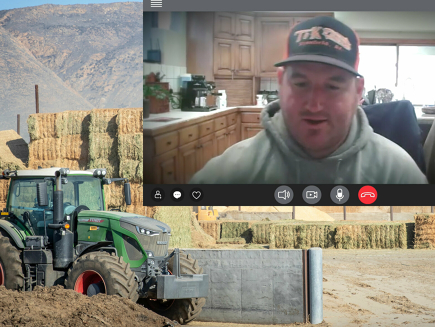

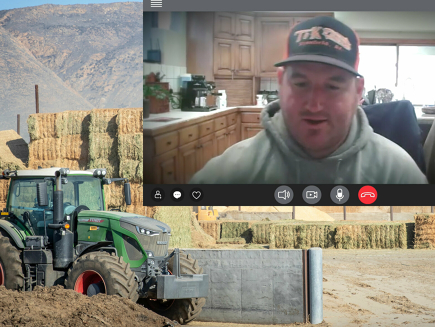

What I've noticed with the Fendt is the fuel economy. As long as you're not foot to the floor, you're getting a lot better fuel economy than other tractors.

Neil Anderson, farmer, Northern California, USA - Fendt 1038, 1042, and 1046 Vario Tractors

Neil Anderson, farmer, Northern California, USA - Fendt 1038, 1042, and 1046 Vario Tractors

What I've noticed with the Fendt is the fuel economy. As long as you're not foot to the floor, you're getting a lot better fuel economy than other tractors.

The CVT transmission maintains the precise speed and engine RPM for fuel efficient operations and power needs.

Scott Schneider, Snowmobile Trail Groomer, Forest County, Wisconsin, USA - Fendt 516 Vario Tractor

Scott Schneider, Snowmobile Trail Groomer, Forest County, Wisconsin, USA - Fendt 516 Vario Tractor

The CVT transmission maintains the precise speed and engine RPM for fuel efficient operations and power needs.

We get a lot done in a shorter amount of time with the Fendt setup.

Roger & Nate Wallace, farmers, Kewanee, Illinois - Fendt Momentum Planter and 1042 Vario Tractor

Roger & Nate Wallace, farmers, Kewanee, Illinois - Fendt Momentum Planter and 1042 Vario Tractor

We get a lot done in a shorter amount of time with the Fendt setup.

Eff

iciency and reliability are what set Fendt apart from other brands.

Donald Lippy, farmer, Carroll County, Maryland, USA - Fendt Momentum Planter, 1050, and multiple 900, 700, and 500 Vario Series Tractors

Donald Lippy, farmer, Carroll County, Maryland, USA - Fendt Momentum Planter, 1050, and multiple 900, 700, and 500 Vario Series Tractors

Eff

iciency and reliability are what set Fendt apart from other brands.

The lower RPM means significant fuel savings.

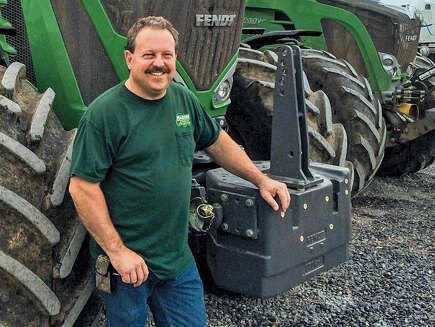

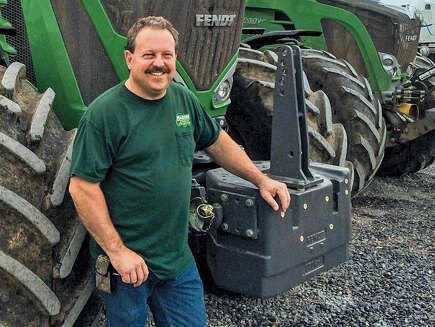

Ramona & Terry Button, farmers, Sacaton, Arizona, USA - Fendt 718, 933, and 1162 Vario Tractors

Ramona & Terry Button, farmers, Sacaton, Arizona, USA - Fendt 718, 933, and 1162 Vario Tractors

The lower RPM means significant fuel savings.

The

variable transmission is so much smoother and so much nicer. Fuel efficiency on the Fendt is a lot better.

Mike & Marty Burken, farmers, Clinton, Iowa, USA - Fendt 1050 Vario Tractor, Momentum Planter and IDEAL Combine

Mike & Marty Burken, farmers, Clinton, Iowa, USA - Fendt 1050 Vario Tractor, Momentum Planter and IDEAL Combine

The

variable transmission is so much smoother and so much nicer. Fuel efficiency on the Fendt is a lot better.

Fendt is a cost-efficient solution. It is very conservative on fuel, which is a good thing for the amount of horsepower it has.

The Raber Family, farmers, Freeport, Ohio, USA - Fendt 716 and 933 Vario Tractors

The Raber Family, farmers, Freeport, Ohio, USA - Fendt 716 and 933 Vario Tractors

Fendt is a cost-efficient solution. It is very conservative on fuel, which is a good thing for the amount of horsepower it has.

What really makes it work is the combination of good equipment, good dealership, good access to parts, and people willing to go the extra mile.

Barry & Rayelle Schmitt, farmers, Olds, Alberta, CANADA - Fendt 500, 700, 900 and 1000 Series Vario Tractors

Barry & Rayelle Schmitt, farmers, Olds, Alberta, CANADA - Fendt 500, 700, 900 and 1000 Series Vario Tractors

What really makes it work is the combination of good equipment, good dealership, good access to parts, and people willing to go the extra mile.

Smooth, suspended front axle, suspended cab, really comfortable seat, and there’s a great sound system. That’s a big thing for me.

Ryan Davidson , farmer, Tioga, North Dakota- Fendt Rogator Sprayer and 724 Vario Tractor

Ryan Davidson , farmer, Tioga, North Dakota- Fendt Rogator Sprayer and 724 Vario Tractor

Smooth, suspended front axle, suspended cab, really comfortable seat, and there’s a great sound system. That’s a big thing for me.

The efficiency is amazing. I ran this tractor probably 20 hours and finally had to fill up.

Bryce Chaffee, rancher, Burbank, Ohio, USA - Fendt 716 Vario Tractor

Bryce Chaffee, rancher, Burbank, Ohio, USA - Fendt 716 Vario Tractor

The efficiency is amazing. I ran this tractor probably 20 hours and finally had to fill up.

The efficiency is amazing. I ran this probably 20 hours and finally had to fill up.”

Tony Hegemann, Newman Grove, Nebraska, USA - Fendt Momentum Planter and 1042 Vario Tractor

Tony Hegemann, Newman Grove, Nebraska, USA - Fendt Momentum Planter and 1042 Vario Tractor

The efficiency is amazing. I ran this probably 20 hours and finally had to fill up.”

The cleanliness of the sample is really good on this combine, and the losses are really low.

Darrin Burka, farmer, Saskatchewan, CANADA - Fendt IDEAL Combine 10T and 1050 Vario Tractor

Darrin Burka, farmer, Saskatchewan, CANADA - Fendt IDEAL Combine 10T and 1050 Vario Tractor

The cleanliness of the sample is really good on this combine, and the losses are really low.

When you compare Fendt tractors to other brands, you're more efficient day in and day out. You get across more acres and burn less fuel.

Andy & Mark Lehenbauer, farmers, Hannibal, Missouri, USA - Fendt Momentum Planter, 714, 828, 942, and 1050 Vario Tractors

Andy & Mark Lehenbauer, farmers, Hannibal, Missouri, USA - Fendt Momentum Planter, 714, 828, 942, and 1050 Vario Tractors

When you compare Fendt tractors to other brands, you're more efficient day in and day out. You get across more acres and burn less fuel.

When you compare Fendt tractors to other brands, they are more efficient, you're not as fatigued, and you get more done with less fuel.

Kevin Holl, farmer, Conrad, Iowa, USA - Fendt 939 Vario Tractor

Kevin Holl, farmer, Conrad, Iowa, USA - Fendt 939 Vario Tractor

When you compare Fendt tractors to other brands, they are more efficient, you're not as fatigued, and you get more done with less fuel.

T

he durability, reliability, and efficiency of the Fendt tractor is world renowned.

Josh De Jong, dairy farmer, California and Arizona, USA - Fendt 500, 700, and 900 Series Vario Tractors

Josh De Jong, dairy farmer, California and Arizona, USA - Fendt 500, 700, and 900 Series Vario Tractors

T

he durability, reliability, and efficiency of the Fendt tractor is world renowned.

The cost to run the Fendt 828 came in at $10 per hour, well under previous equipment.

Johnny Hoffman, manager, Oakridge Dairy Farm, Pennsylvania, USA - Fendt 824, 828, and 930 Vario Tractors

Johnny Hoffman, manager, Oakridge Dairy Farm, Pennsylvania, USA - Fendt 824, 828, and 930 Vario Tractors

The cost to run the Fendt 828 came in at $10 per hour, well under previous equipment.

The Fendt 1050 has been a major game changer - we’re talking in the tens of thousands of dollars worth of savings a year.

Michel & Hanneke Camps, farmers, Barnwell, Alberta, CANADA - Fendt 512, 720, 828, 936, and 1050 Vario Tractors

Michel & Hanneke Camps, farmers, Barnwell, Alberta, CANADA - Fendt 512, 720, 828, 936, and 1050 Vario Tractors

The Fendt 1050 has been a major game changer - we’re talking in the tens of thousands of dollars worth of savings a year.

The tractor and the planter together float across the field with ease - Nate Rogers

Central Illinois Farmers (Alan Johnston, Kreg Main, Roger & Nate Wallace), USA - Fendt Momentum Planter and 1042 Vario Tractor

Central Illinois Farmers (Alan Johnston, Kreg Main, Roger & Nate Wallace), USA - Fendt Momentum Planter and 1042 Vario Tractor

The tractor and the planter together float across the field with ease - Nate Rogers

There is a growing following of farmers in the area that rely on Fendt as their workhorses.

RM Taché Public Works, Winnipeg, Manitoba, Canada, Fendt 716 and 718 Vario Tractors

RM Taché Public Works, Winnipeg, Manitoba, Canada, Fendt 716 and 718 Vario Tractors

There is a growing following of farmers in the area that rely on Fendt as their workhorses.

When you’re in a field and you need a little more power, you don’t have to worry about it with Fendt tractors.

Danny Floyd, Thomas, Oklahoma, USA, Fendt 1042, 700 and 900 Vario Series Tractors

Danny Floyd, Thomas, Oklahoma, USA, Fendt 1042, 700 and 900 Vario Series Tractors

When you’re in a field and you need a little more power, you don’t have to worry about it with Fendt tractors.

I love never having the same day twice. I enjoy facing different challenges each day and learning from past experiences.

Matt Barnard, farmer from Foosland, Illinois, USA - Fendt IDEAL Combine, Momentum Planter, and 1000 Vario series

Matt Barnard, farmer from Foosland, Illinois, USA - Fendt IDEAL Combine, Momentum Planter, and 1000 Vario series

I love never having the same day twice. I enjoy facing different challenges each day and learning from past experiences.

Both models offers a great peace of mind. I have confidence in these two machines and they make us look forward to the upcoming harvest seasons at all times.

Both models offers a great peace of mind. I have confidence in these two machines and they make us look forward to the upcoming harvest seasons at all times.

When I borrowed the Fendt 700 Vario-series demonstrator from the local Crawfords Billingshurst depot I didn’t expect to buy it, but within 30 minutes of it arriving on the farm I just didn’t want to give it back

When I borrowed the Fendt 700 Vario-series demonstrator from the local Crawfords Billingshurst depot I didn’t expect to buy it, but within 30 minutes of it arriving on the farm I just didn’t want to give it back

isn´t likely to be the last Fendt I own.

isn´t likely to be the last Fendt I own.

by the time you add all the

features that Fendt includes as

standard equipment.

by the time you add all the

features that Fendt includes as

standard equipment.

really is stepless.

really is stepless.

I know exactly what Fendt tractors can do and that they deliver what they promise.

I know exactly what Fendt tractors can do and that they deliver what they promise.

I’ve always liked Fendt - the best of all the tractors I’ve operated.

I’ve always liked Fendt - the best of all the tractors I’ve operated.

600 ha grass with 3 Fendt IDEAL 9T.

600 ha grass with 3 Fendt IDEAL 9T.

Review: Farewell to fatigue with IDEALDrive.

Review: Farewell to fatigue with IDEALDrive.

It’s quite simple really – leaders drive Fendt!

It’s quite simple really – leaders drive Fendt!

We'd be

nowhere near as flexible if

we used trucks.

We'd be

nowhere near as flexible if

we used trucks.

You get to turn something really bad into something really good.

You get to turn something really bad into something really good.

With our LAYJET method, we are on average 10 times faster than with conventional technology.

With our LAYJET method, we are on average 10 times faster than with conventional technology.

I couldn't ask any more of this tractor.

I couldn't ask any more of this tractor.

We didn't have to re-learn anything, because the chopper works like the tractor.

We didn't have to re-learn anything, because the chopper works like the tractor.

working speed 0.4 km/h.

working speed 0.4 km/h.

The newer technology for track guidance with the Countour Assistant and VCR together with the good conditions has convinced me.

The newer technology for track guidance with the Countour Assistant and VCR together with the good conditions has convinced me.

So far, no other machine has been able to match the grain quality of the Fendt IDEAL.

So far, no other machine has been able to match the grain quality of the Fendt IDEAL.

Up to 25% of the costs for fertiliser can be saved.

Up to 25% of the costs for fertiliser can be saved.

For us, the key factor is machine reliability, in other words, not prone to breaking down.

For us, the key factor is machine reliability, in other words, not prone to breaking down.

This machine is unique. The elevating cab gives the operator an unparalleled view of the loader and the material being processed.

This machine is unique. The elevating cab gives the operator an unparalleled view of the loader and the material being processed.

The Fendt cab is much larger and offers excellent visibility. The lighting system is ideal for working at night.

The Fendt cab is much larger and offers excellent visibility. The lighting system is ideal for working at night.

We have been using Fendt tractors on our farm for a good 17 years and have always had good experiences.

We have been using Fendt tractors on our farm for a good 17 years and have always had good experiences.

The threshing system works well and offers excellent quality of both grain and straw, practically without grain losses

The threshing system works well and offers excellent quality of both grain and straw, practically without grain losses

One very important reason was the low-speed technology of the MAN engine.

One very important reason was the low-speed technology of the MAN engine.

This year, we achieved daily outputs of over 1,000 m3 with our new draught horse, which is quite astonishing under the conditions prevailing here.

This year, we achieved daily outputs of over 1,000 m3 with our new draught horse, which is quite astonishing under the conditions prevailing here.

At 40 km/h, the speed is only 950 rpm, which of course makes the job a lot more relaxed for the drivers.

At 40 km/h, the speed is only 950 rpm, which of course makes the job a lot more relaxed for the drivers.

The 942 is easy going and overall a mature concept.

The 942 is easy going and overall a mature concept.

The 415 hp from the MAN engine with 9 l displacement, coupled with the low-speed concept, are optimal for chipper use.

The 415 hp from the MAN engine with 9 l displacement, coupled with the low-speed concept, are optimal for chipper use.

The soils place high demands on people and technology.

The soils place high demands on people and technology.

One day too late in spring is one day less for the potatoes to grow in autumn.

936, 1050 Vario

936, 1050 Vario

One day too late in spring is one day less for the potatoes to grow in autumn.

I'm glad that Fendt gives us an open system which we can use to incorporate the data via the agrirouter into a field database. It means we can offer a more comprehensive service to the customer.

I'm glad that Fendt gives us an open system which we can use to incorporate the data via the agrirouter into a field database. It means we can offer a more comprehensive service to the customer.

A fast harvest in crucial for the quality of macadamia nuts.

A fast harvest in crucial for the quality of macadamia nuts.

We are productive because we have a reliable machine.

We are productive because we have a reliable machine.

It´s nice and neat in the barley, wheat and here in the rapeseed.

It´s nice and neat in the barley, wheat and here in the rapeseed.

With the Fendt 6335 C PLI we practically have no losses.

With the Fendt 6335 C PLI we practically have no losses.

Tracks are a Must.

Tracks are a Must.

Fendt IDEAL sets new standards.

Fendt IDEAL sets new standards.

They are reliable, economical, value-retaining, and fit perfectly into the philosophy of our company.

They are reliable, economical, value-retaining, and fit perfectly into the philosophy of our company.

I love new machines. I can sell my used machines for a good price and, ideally, not have any downtime for repairs during the harvest time.

I love new machines. I can sell my used machines for a good price and, ideally, not have any downtime for repairs during the harvest time.

We love riding on the Fendt to the different filming locations.

We love riding on the Fendt to the different filming locations.

The powerful pump meant I was able to significantly increase the output compared to the old technology.

The powerful pump meant I was able to significantly increase the output compared to the old technology.

The VarioGuide Contour Assistant and its new wayline types – Contour Segments and Single Track – are a big plus for Fendt when it comes

to potato planting.

The VarioGuide Contour Assistant and its new wayline types – Contour Segments and Single Track – are a big plus for Fendt when it comes

to potato planting.

The guidance functions especially are made even simpler with FendtONE.

The guidance functions especially are made even simpler with FendtONE.

But the Fendt won in the end because it just makes economic sense.

But the Fendt won in the end because it just makes economic sense.

The best thing about my decision to switch to Fendt are the fuel savings I make.

The best thing about my decision to switch to Fendt are the fuel savings I make.

The Fendt makes our working day much easier thanks to the easy controls.

The Fendt makes our working day much easier thanks to the easy controls.

There’s probably no tractor brand that can compete with the precision of Fendt’s Vario transmission.

There’s probably no tractor brand that can compete with the precision of Fendt’s Vario transmission.

We can save ourselves having to buy another tractor.

We can save ourselves having to buy another tractor.

The technology sounds complex, but it's so easy to use.

The technology sounds complex, but it's so easy to use.

The short transition times and the excellent threshing results on the slope

are very important for us.

The short transition times and the excellent threshing results on the slope

are very important for us.

The interplay between the engine and gearbox is as efficient as it gets.

The interplay between the engine and gearbox is as efficient as it gets.

On a Fendt, the gearbox and engine work without any loss of power, even in difficult ground conditions.

On a Fendt, the gearbox and engine work without any loss of power, even in difficult ground conditions.

This is where the VisoPlus cab of the 700 model is just perfect.

This is where the VisoPlus cab of the 700 model is just perfect.

It's an excellent system that will help make data management even easier, as development advances.

It's an excellent system that will help make data management even easier, as development advances.

Tractor development then gave us the gift of the Vario gearbox for vineyard tractors, making it easier to work comfortably in the cab.

Tractor development then gave us the gift of the Vario gearbox for vineyard tractors, making it easier to work comfortably in the cab.

I’m responsible for 1,850 hectares of crops.”

I’m responsible for 1,850 hectares of crops.”

It's all about diversity. That's why we call the tractor a multipurpose machine.

It's all about diversity. That's why we call the tractor a multipurpose machine.

There's a level interplay of operational requirements, product and service.

There's a level interplay of operational requirements, product and service.

Fendt tractors are enormously efficient with regard to time, quality and fuel.

Fendt tractors are enormously efficient with regard to time, quality and fuel.

The Fendt 200 series can more than hold its own in this weight class.

The Fendt 200 series can more than hold its own in this weight class.

It is the only tractor that our operators want to sit in for 12-hour shifts. It is more comfortable, easier to operate, and we also make significant fuel savings over alternatives

It is the only tractor that our operators want to sit in for 12-hour shifts. It is more comfortable, easier to operate, and we also make significant fuel savings over alternatives

The quality is impeccable and the same goes for comfort.

The quality is impeccable and the same goes for comfort.

Very compact and fine bales with good density, and the maintenance of the machine has been easy to handle.

Very compact and fine bales with good density, and the maintenance of the machine has been easy to handle.

England - Fendt IDEAL 8

England - Fendt IDEAL 8